Take your work station

anywhere

Ellan

In the era of extreme productivity, having a mobile workshop is no longer a differentiator — it has become a strategic necessity. For maintenance, technical assistance, telecom, and field service companies, transforming a utility vehicle into a compact, safe, and highly organized work unit is the key to gaining agility, reducing logistics costs, and delivering superior service.

This practical guide presents a step-by-step approach to this conversion, going far beyond simple adaptations and focusing on maximum performance.

Comparing a well-structured mobile workshop with a traditional workshop or constant trips back to base reveals decisive advantages:

The return on investment (ROI) is clear: more productivity, lower indirect costs and higher customer satisfaction.

Everything starts with selecting the right vehicle. The model should consider:

Here, Ellan is your strategic partner. With our experience, we identify the ideal base for your operation and work with your existing vehicle or help define the best acquisition, ensuring an efficient and hassle-free starting point.

This is the moment to define workflow within limited space. Think in functional zones:

With Ellan, you have a specialist by your side. Our engineers map your real workflow to design a layout that maximizes every centimeter, creating an ergonomic and logical environment for field teams.

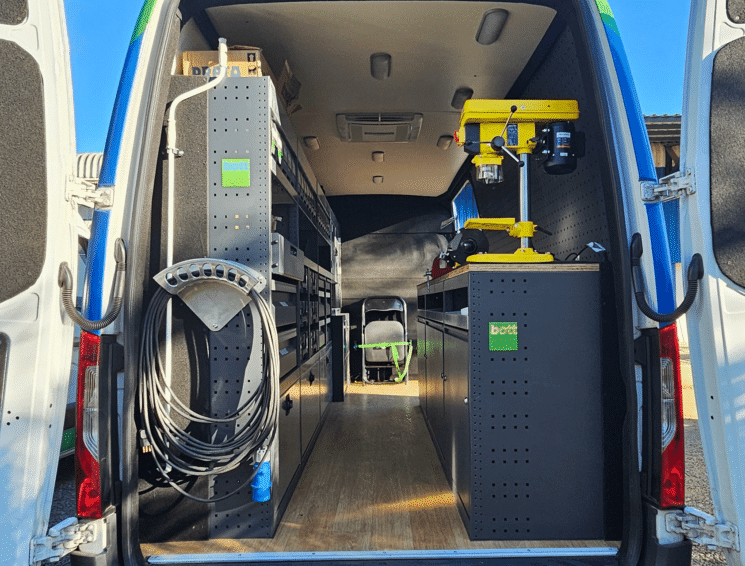

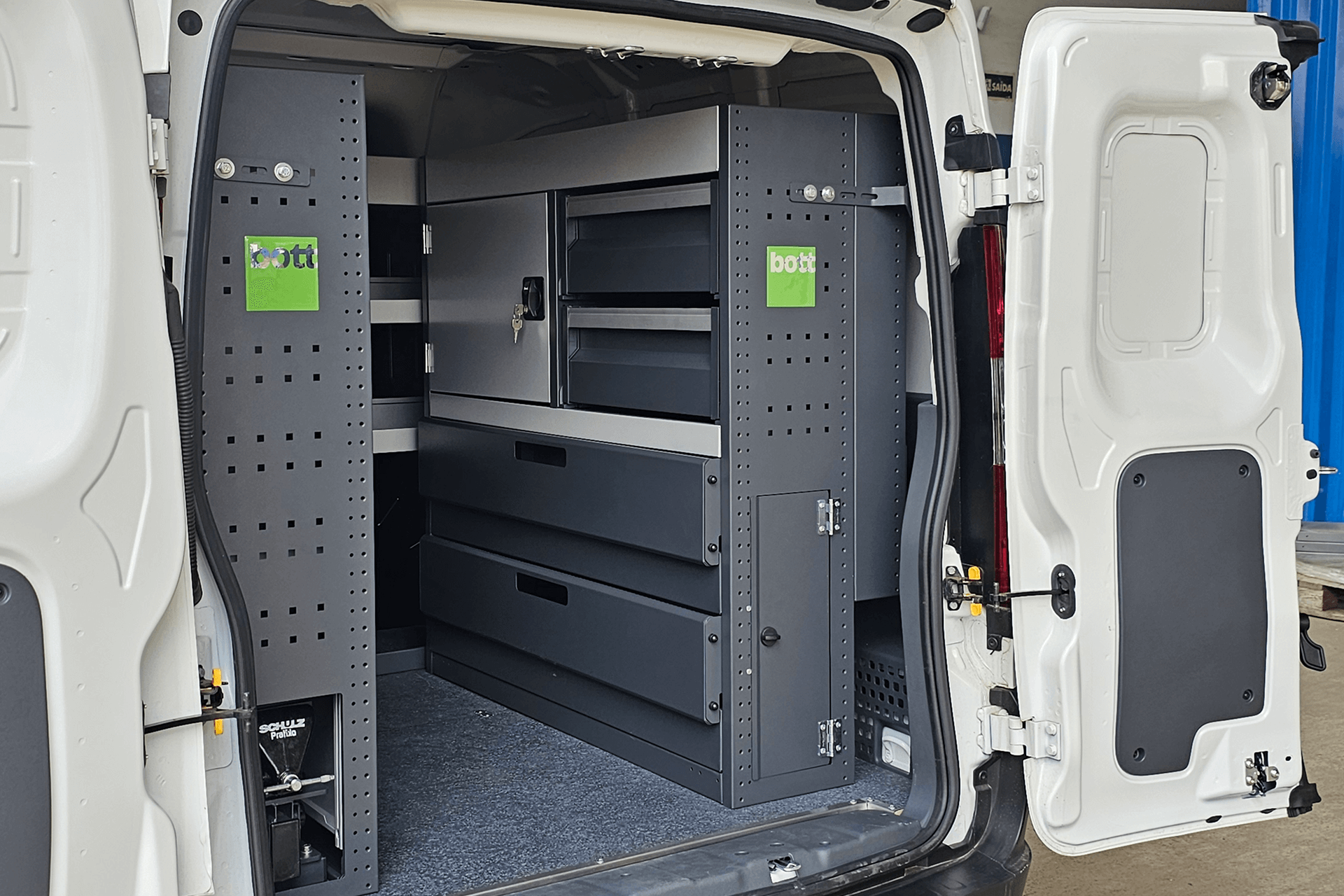

This is the stage that turns an empty space into a productive system. Bott technology is the backbone of this transformation. Its principle of total technical organization through modular systems perfectly fits mobile challenges.

As the exclusive Bott licensee in Brazil, Ellan brings this global standard to your operation. We implement a philosophy that turns chaos into productivity, where technicians solve problems instead of searching for tools.

Each activity has specific requirements:

At Ellan, we start with sector-optimized projects. Our expertise allows us to quickly adapt solutions to your business needs, delivering proven performance from day one.

Transforming your vehicle into a high-performance mobile workshop is a strategic project. It requires planning, proven-quality products, and a deep understanding of ergonomics and productivity in compact spaces.

At Ellan, we combine Bott’s organizational philosophy and technology with years of applied engineering experience to develop the ideal mobile solution for your business. From design to installation, we ensure a work environment that elevates efficiency and safety in field operations.

Stop wasting time and money on disorganization. Talk to one of our specialists on WhatsApp now and take the first step toward the mobile workshop your business needs.

Take your work station

anywhere